F*ck Reddit and Facebook for blocking information about protecting communities from ICE

Facebook and Reddit are blocking access to a site that unmasks otherwise anonymous ICE thugs. F*ck you Reddit and Facebook.

Facebook and Reddit are blocking access to a site that unmasks otherwise anonymous ICE thugs. F*ck you Reddit and Facebook.

So here are the resources being blocked:

- ICEList - the goal is to unmask these thugs. Crowd-sourced identities of ICE Nazis.

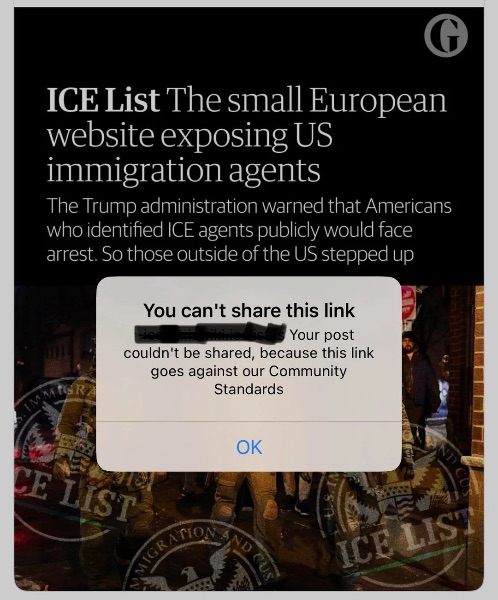

- Article about ICEList in The Guardian - this is the article that Reddit is blocking